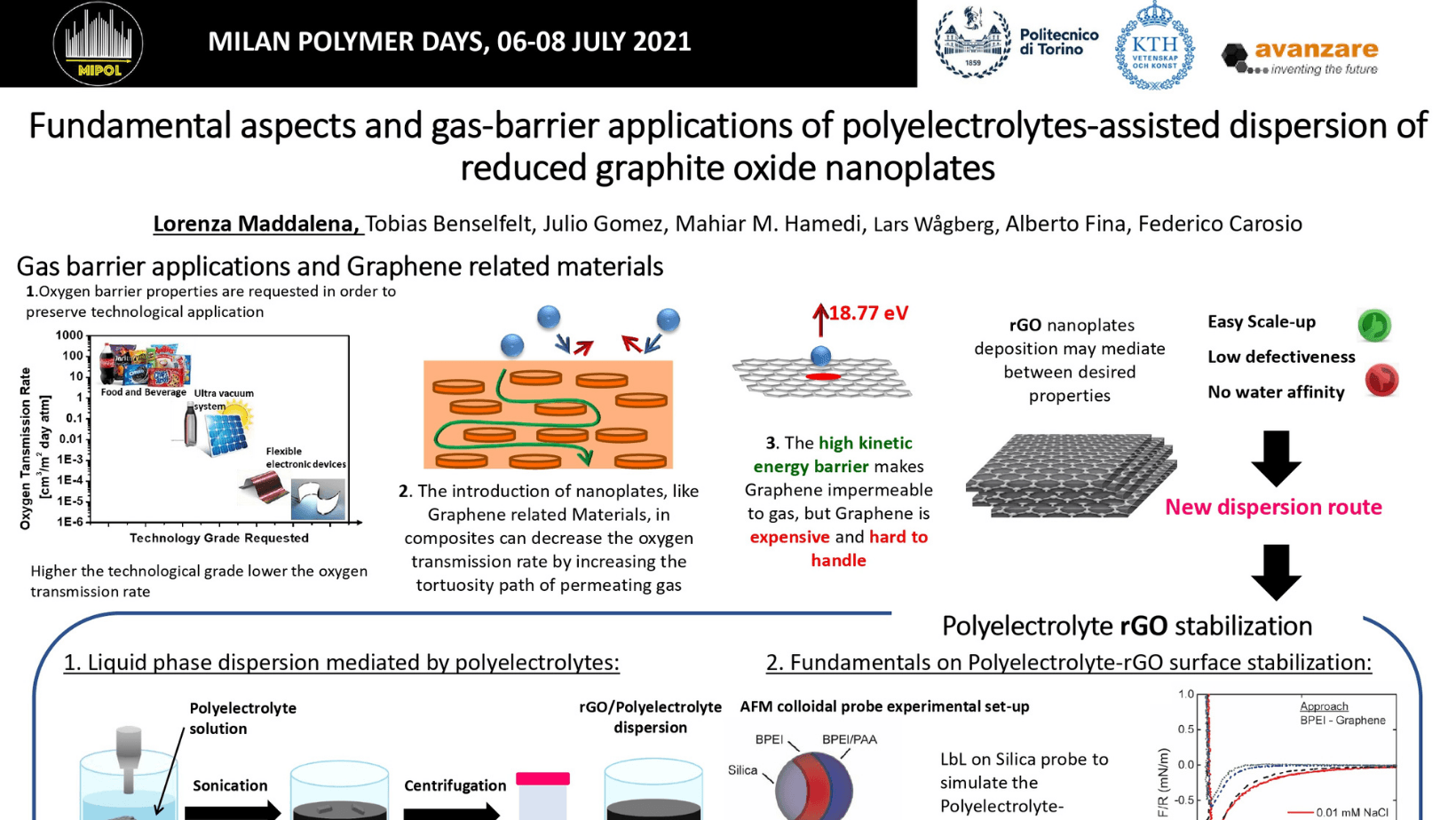

Fundamental aspects and gas-barrier applications of polyelectrolytes-assisted dispersion of reduced graphite oxide nanoplates

Most of goods used in our everyday life (e.g food, electronic devices, pharmaceutical products) need a packaging able to satisfy a lot of requisites like transparency, protection against pollutants and barrier to gasses. This latter must be higher as higher is the technological grade of goods to be protected, such as flexible electronic devices of pharmaceuticals. One of the most attractive material for packaging applications is graphene.

Graphene is a monolayer of sp2 carbon atoms arranged in a honeycomb structure and in the last 10 years has attracted the interest of both the scientific and industrial community because of its exceptional performance in terms of mechanical and optical properties and electrical conductivity. In addition, graphene shows a very high energy for the penetration of atoms and molecules, which would prevent any gases and liquids from passing through it at room temperature. These properties make graphene very attractive for the development of advanced packaging materials.

My name is Lorenza Maddalena and I’m a post-doc researcher in the Politecnico di Torino where I study graphene related materials as building block for the preparation of coatings able to enhance gas barrier properties of substrates normally used as packaging material.

In my work I employed negatively and positively charged polyelectrolyte water-based solutions in order to stabilize graphene nanoplates and I used these suspensions for the layer by layer assembly of a coating on a thin PET film, a very common polymer used in packaging. The coating is obtained by the electrostatic interaction between positive and negative charges of polyelectrolytes and results in a “brick and mortar” configuration were the graphene nanoplates can be considered bricks glued together by the polyelectrolytes chain. The coated PET exhibited a very low oxygen permeability and a very high transparency thus opening to the possibility to use this approach for the development of advanced packaging solutions for flexible electronic devices.