Wood – polymer composites with hydrophobic properties

Angelika Macior (a),Izabela Zaboriak (b), Paweł Chmielarz (b), Joanna Smenda (c) and Karol Wolski (c) (a) Doctoral School of Engineering and Technical Sciencees at the Rzeszów University of Technology (b) Department of Physical Chemistry, Faculty of Chemistry, Rzeszów University of Technology (c) Faculty of Chemistry, Jagiellonian University

The subject of my research is the preparation of wood-polymer composites with hydrophobic properties.

Based on the principles of green chemistry, bringing together the need to create ecologicalmaterials while exploring the unique properties of wood, polymer modification is of particular interest. Wood is a unique material, or rather a natural polymer composite, widely available in nature.It attractslots of attentiondueto its unique physical/chemical structure, easy processing, and biodegradability. Wood’s greatest disadvantage is hydrophilicity; moist wood is sensitive to microorganisms and fungi attacks, resulting in the loss of dimensional stability, which limits the usage and lifespan of wood.

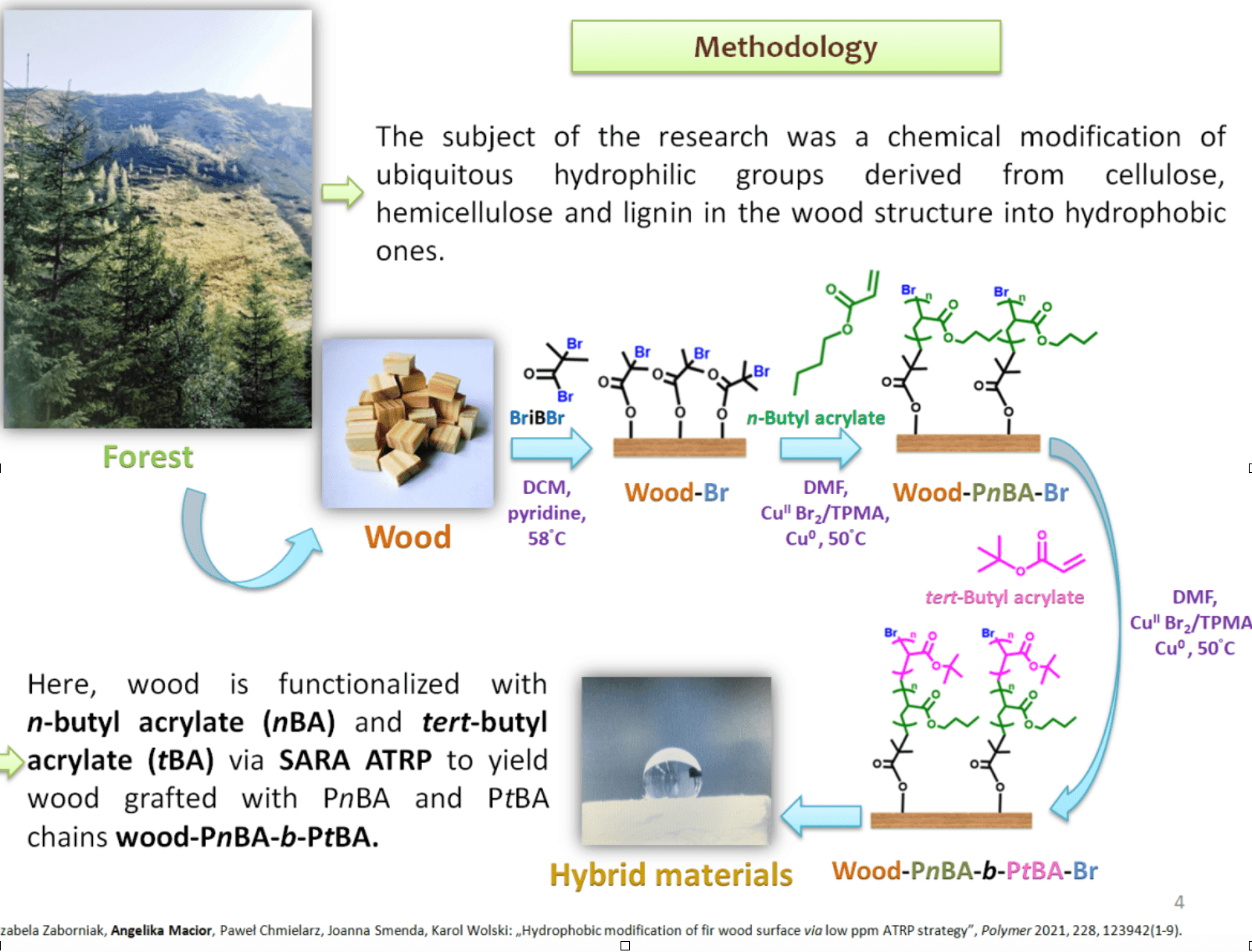

In response to this issue, knowing that numerous hydroxyl groups in wood structure cause its hydrophilicity, the subject of the research was a chemical modification of the common hydrophilic groups derived from cellulose, hemicellulose and lignin into hydrophobic ones.

This method comprises of two steps:

-

Firstly, an esterification reaction of hydroxyl/phenolic groups with α-bromoisobutyryl bromide is conducted, adding initiator functionality to the wood surface.

-

Secondly, the received brominated wood is polymerized with different monomers with the use of the “grafting from” method to generate wood-derived bioconjugates with certain properties.

Now, a few words about the wood modification by ATRP.

Differently from other studies, we use ATRP with an emphasis on methods carried out with diminished amounts of catalyst.

The conceptis focused on grafting of hydrophobic polymers – poly(n-butyl acrylate) (PnBA) and poly(tert-butyl acrylate) (PtBA) from wood using supplemental activator and reducing agent (SARA) ATRP with copper wire as a reducing agent. Novel wood-polymer composites were characterized by the controlled structure of the tethered polymer brushes. This is proved by low dispersity (Mw/Mn) and predefined molecular weight (MW) of polymers grown in the reaction mixture.

Table 1. Analysis of thepolymers produced in the reaction mixture during surface-initiated SARA ATRP of acrylates from wood (1)

(1) General conditions: T = 50°C; Vtot = 50 mL; t = 1.60 h for entry 1, t = 1.33 h for entry 2; [Monomer]0/[EBiB]0/[CuIIBr2/TPMA]0 = 1,000/1/0.2. SARA ATRP with copper wire: d = 0.1 cm, l = 40 cm.

Moreover, the prepared hybrid materials were visualized by scanning electron microscope (SEM) clearly indicating the modification of the wood surface with polymers.

The objective of wood modification was to increase its water repellence. To confirm improvement in hydrophobicity of the polymer-coated wood specimens, water contact angle (Θ) measurements were conducted. The results showed that:

-

Unmodified wood is characterized by high hydrophilicity due to the presence of hydroxyl groups in the structure.The initial water contact angle was ~41°, and the water drop soaked into the wood surface after 5 s.

-

Wood modified with polyacrylates displayed an excellent hydrophobic property.The water contact angle ranged from ~138° for wood specimens grafted with homopolymer chains to ~117° for wood surfaces modified with block copolymers. They were exposed to water droplets for 120 s.

Conclusion:

-

Scanning electron microscope (SEM) analysis of the prepared hybrid materials clearly indicates the modification of the wood surface with polymers.

-

Water contact angle (Θ) measurements prove excellent hydrophobic properties of the prepared biohybrid material (Θ ~138°) without notable changes after 120 s of water droplet exposure.

-

The presented conceptallowed for the production of ecological and environmentally friendly approachesto improving the properties of wood. Particular emphasiswas placedcreatingan efficient hydrophobic polymer coverage on the wood surface characterized by highstability.

Financial support:

We acknowledged the financial support from Minister of Education and Science under the programme "Students Research Clubs creates innovations" (Contract no: SKN/SP/496557/2021) P.C. acknowledges Minister of Science and Higher Education scholarship for outstanding young scientists (0001/E-363/STYP/13/2018).

Additional information about the topic can be found at the following links:

https://www.sciencedirect.com/science/article/pii/S0032386121005656

https://pchmielarz.v.prz.edu.pl/

https://twitter.com/Chmielarz_Group